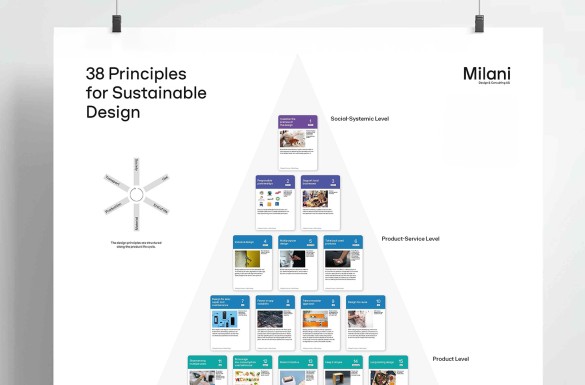

38 sustainable design principles explained

Design for easy Repair and Maintenance: A Sustainable Approach in Product Design

California and France are requiring it, Europe is planning it, and consumer advocates are pushing for it: Designing for easy repair and maintenance is not only one of the most powerful strategies in designing for a circular economy, it will soon become a new legal norm for certain products.

In this blog post, we'll look at the principle itself, explore its benefits for businesses, and highlight successful case studies.

Design for easy Repair and Maintenance

Briefly explained

Companies and product designers can use different design principles to create more sustainable products. Among these principles, design for easy repair and maintenance stands out as it breaks the cycle of ‘take-make-dispose’ and focuses on extending the product life.

Design for repair focuses primarily on making products easily repairable when they break, while design for maintenance aims to reduce the difficulties and costs associated with regular servicing and preventive maintenance of products. Easy repair and maintenance can be done by end users (self-repair) as well as by professionals (either the manufacturer or a third party service provider).

Design for repair and maintenance is already widespread in capital goods, where investment costs can be very high and the replacement or repair of damaged parts usually involves maintenance. However, repair in the consumer goods sector is relatively new, as most products are designed for a single life or even planned obsolescence.

The benefits

Designing for repairability makes it easier and less expensive to repair when products break or fail. This extends the life of these products, reduces waste and landfill impact, and conserves resources.

Designing for repair and maintenance also offers several business benefits. Companies can strengthen their brand reputation and customer loyalty by building a reputation for producing reliable, more sustainable products. They can also reduce warranty claims and lower replacement costs. Exciting new business opportunities arise. In addition to traditional sales, companies can generate revenue from repair and maintenance services, spare parts and upgrades. It is therefore an effective strategy for designing for the circular economy.

From Europe to the United States

Increasing legislative pressure

France was the first country in Europe to introduce a legally binding repairability index in 2021 for certain electronic and electrical equipment, such as smartphones, televisions and certain household appliances. Manufacturers must provide repairability scores for their products and inform consumers at the point of purchase about the ease of repair. They must also provide repair manuals and spare parts. Similar measures have been adopted in the UK, and are outlined in Belgium. As a result, the European Commission is planning a Europe-wide repairability index to be introduced in 2025, and linked to an energy efficiency label.

Right to repair legislation is also gaining momentum in the United States. After New York, Colorado, and Minnesota, California is the latest state to sign the Right to Repair Act into law. It requires manufacturers to make tools, parts, software, and documentation for electronic devices costing more than $100 available to consumers and independent repair shops, for seven years after manufacture, or three years for less expensive devices.

Case

SHIFT offers consumer-friendly, repairable smartphones and headphones

SHIFT, a small family-owned German technology company, is at the forefront of sustainable design with its repairable smartphone, laptop, and headphones. Unlike many similar products on the market, which are notoriously difficult to repair due to their tightly integrated components, SHIFT products are designed to be modular. Customers can easily replace key components, such as batteries, screens, and cameras, without special tools or expertise and without losing their product warranty.

By providing user-friendly, easy-to-use repair guides and selling spare parts, SHIFT empowers its customers to take care of their own maintenance and extend the life of their equipment. This benefits customers' budgets and significantly reduces e-waste.

SHIFT's approach demonstrates that it's possible to combine cutting-edge technology with sustainable design, proving that repairability and innovation can go hand in hand.

Case

Thermoplan shakes up the coffee industry with its modular coffee machines

The Swiss company Thermoplan, which supplies industrial coffee machines to companies such as Starbucks, McDonald's, and IKEA, is offering new services to the B2B coffee industry. While it's normal for coffee machine parts to wear out or need replacing over time, Thermoplan ensures that this process is done with minimal disruption. The machines are modular, with easily replaceable parts. For example, if a particular component needs to be replaced, such as the grinder, milk frother or brewing unit, it can be easily replaced in minutes without the need for extensive technical knowledge.

This approach not only reduces the downtime and costs associated with sending a coffee machine in for repair, a crucial advantage in the hectic day-to-day life of the catering industry, but also minimizes the need to replace the entire machine. This makes Thermoplan products a cost-effective solution for coffee shops and businesses. Thermoplan demonstrates that even in the world of commercial equipment, designing for easy repair and maintenance can have a significant positive impact on both business and the environment.

case

Philips offers products as a service to healthcare facilities

Philips is taking design for easy repair maintenance to new level, completely reversing the traditional business model of product ownership. Instead of selling certain medical equipment, the world leader in healthcare technology offers products as a service to healthcare institutions and care facilities. This means that Philips retains ownership of the medical equipment and only charges for the ongoing maintenance, repair and timely replacement or upgrade of the equipment, which can be on-site or remote. Philips pioneered the Product as a Service concept in 2015, when it first offered Lighting as a Service to Amsterdam's Schiphol Airport. Since then, it has gradually extended this novel circular economy business model to other products, such as MRIs or even portable ultrasound devices.

It's a win-win situation for customers and Philips. Faced with increasing cost pressures and limited budgets, healthcare institutions don't need to make large upfront investments in expensive medical equipment. They can reduce disruptions caused by downtime of critical medical devices and improve patient access to innovative care. On the other hand, Philips benefits from new, regular revenue streams, as well as more touch points and long-term contracts with customers. Because this approach is built on an extended enterprise ecosystem, Philips can offer a wide range of services, from flexible pay-per-use models to regular subscription models, to suit different customers. In addition, Philips can collect, refurbish and resell products that are no longer used, producing them at a lower cost than manufacturing them from scratch.

Best practice tips from Milani

What you need to consider when designing for repair and maintenance

Do you also want to design products that are optimized for easy repair and maintenance? Then we recommend the following best practices:

- Make sure your products have a modular design and consist of individual, interchangeable, and standardized components. They should also be easy to disassemble and reassemble. This makes repair, maintenance and replacement of components easier, more efficient and even cheaper.

- Foresee upgradeability. Electronic and software-based products in particular quickly become obsolete.

- Offer spare parts and make them available for the time required by law - or even longer.

- Involve users and maintenance personnel in the design process to understand their needs, preferences, and behaviors. Not only will you create intuitive products that inspire, but you will also understand the challenges and business opportunities associated with maintenance and repair.

- Empower customers to do their own maintenance and repair: Provide easy-to-use guides and tools, or provide training and professional support.

- What about setting up your own repair and maintenance service? Not every customer wants to repair products themselves and appreciates a convenient service.

- Be creative and explore new service-based business models, from repair and maintenance to upgrades and parts sales. This is how you can successfully leverage the circular economy for your business.

Curious to learn more? You can combine the design principle of easy repair and maintenance with other exciting sustainable design principles. Get inspired by our 38 sustainable design principles.

Blogpost written by Nadine Wolf and Timon Becker.